Welcome to our websites!

Shanghai SIHUA automatic quality scaffold deck roll forming machine

| Weight | About 50000 KGS | Size | 35*4*3.9m (Length*Width*Height) |

| Roller Stations | 30-36 (depends On Final Design) | Roller Shafts Diameter | 70-90mm |

| Roll Forming Speed | 15-25m/min | Forming Rollers Material | CR12MOV VACUUM HEAT TREATMENT |

| Motor power | 30kw+2kw*2pc servo motor | Production size | 190mm/260mm/300mm/320mm |

| Main parts | |||

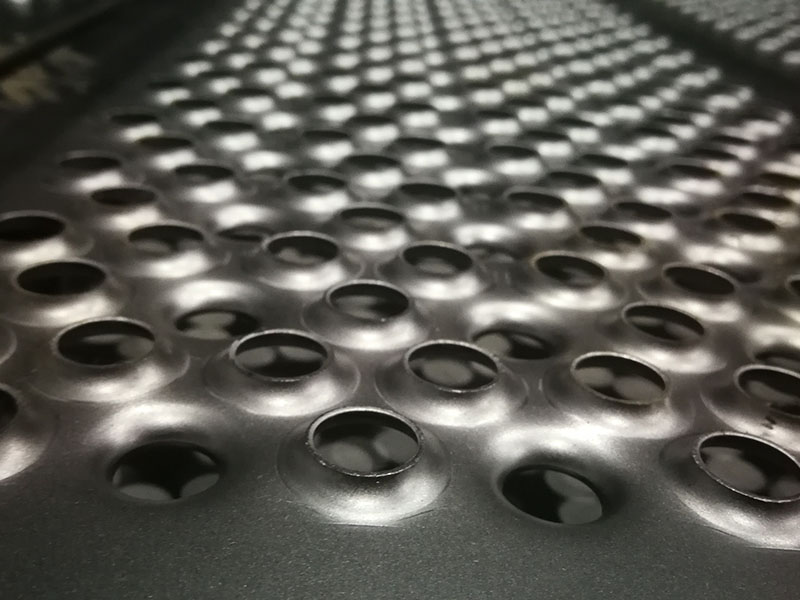

| Slot cutting die | Punching holes die | Forming holes die | Punching logo/tracking NO. die |

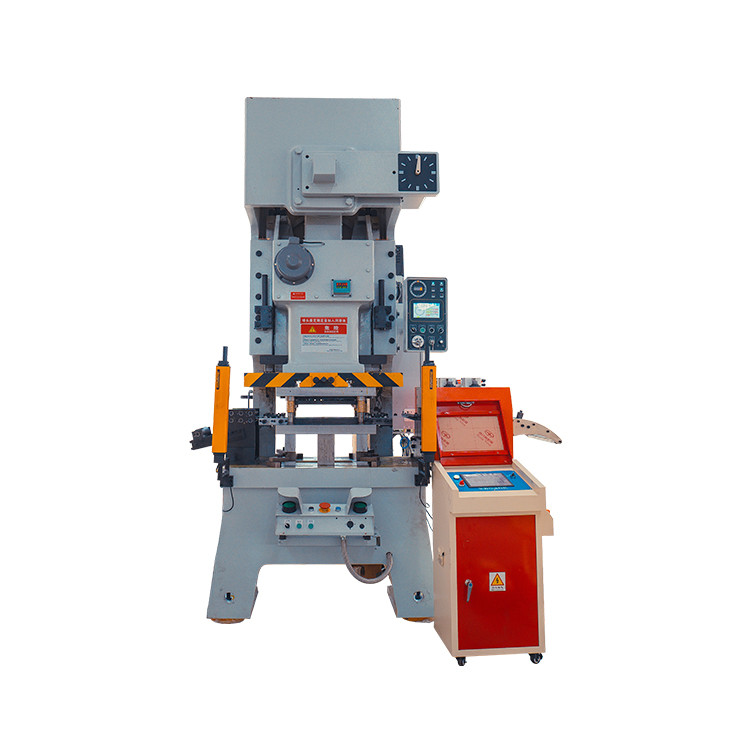

| 3 in 1 COMBI | Press machine capacity: 400ton | Forming machine | Shear cutting off table |

| Packing table | Received profile Robot | Electric control system | Hydraulic station |

Model Number: SHM-HVAC40

Scaffold deck is produced by galvanized sheet or black coil rolling to shape. The cross-sections including V-shape, U-shape, Trapezoid-shape and Wave-shape. It mainly used as the permanent shuttering. It is widely used for the multiple layers steel structure constructions, such as exhibition halls, steel structure plants.

| Weight | About 50000Kgs |

| Size | About 35*4*3.9m (length x width x height) |

| Suitable Raw Material | Galvanized or Galvalume Coils |

| Coil Thickness | 1.0-2.0mm |

| Coil Yield Strength | 235Mpa/350MPA |

| Diameter of forming rollers shafts | 85mm |

| Roll Forming Speed | 15-25/min |

| Forming rollers material | CR12MOV VACUUM HEAT TREATMENT |

| Cutter material | SKD11 (IMPORT FROM JAPAN) |

| Controlling system | PLC and Converter |

| Main motor power | 2x15kw |

| Hydraulic unit motor power | 7.5kw |

| Electric voltage | According to customer's requirement |

| Other requirement | Custom |

Write your message here and send it to us