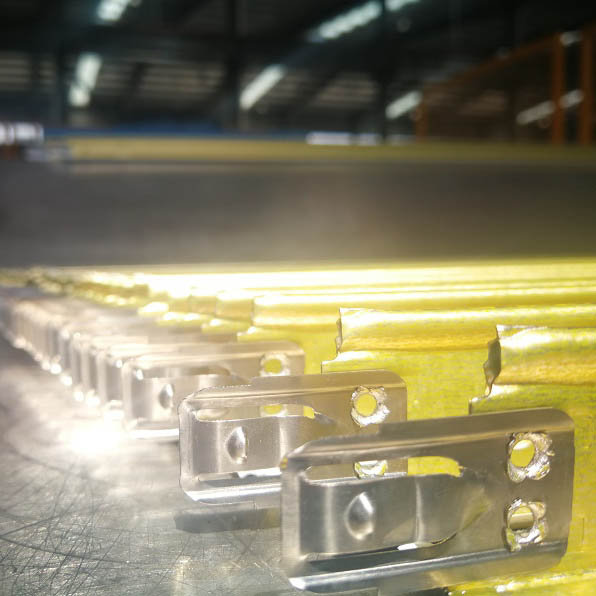

Alloy connector cross t bar roll forming machine

Machine name: Alloy connector SIHUA Cross-T bar production line.

Automatic high speed high precision long and short cross t bar roll forming machine.

Product sizes

1. 25H*24*1220mm(4')/1200

2. 25H*24*610mm(2')/600

We design the machine do according to your confirmed drawing.

Machine Introduction

1.1. T-Bar production line can be monitored by PLC. If the T-bar production line has errors, the PLC will locate the errors. It is easy to maintenance for workers.

1.2. Cross T-Bar Production speed:

1.2.1: 4'=38M/MIN (1 minute to produce 30PC).

1.2.2: 2'=33M/MIN (1 minute to produce 52PC).

1.3. The machine can produce product specifications: 26*24cross-T.

Different spcifications exchange cassette rollers can be replaced in 30 minutes.

For example: 26H *24 specifications can be produced if add one set exchange cassette rollers.

1.4 Electric power: 25kw

Voltage: 380v/400v/415v 3-phase 50/60hz or as custom need.

Annoy connector cross t bar profile

Roll forming machine

Shearing cutting off system