U purline cable tray roll forming machine

| Items | Specifications | |

| Material of coil | Material Width | 200-950mm |

| Material Thickness | 0.8-2.0mm | |

| Uncoiler | 6 tons manual | |

| Forming system | Rolling Speed | 20-40m/min |

| Roller Stations | 18 stations | |

| Roller Material | CR12MOV | |

| Shaft DIA | 70mm | |

| Main Motor Power | 22kw | |

| Cutting system | Material Of Cutting | SKD11(import from JAPAN) |

| Hydraulic cutting Power | 11kw | |

| Electrical

control system |

Electric Source | 380V, 50HZ,3 phase |

| Control System | PLC (MISUBUSHI) |

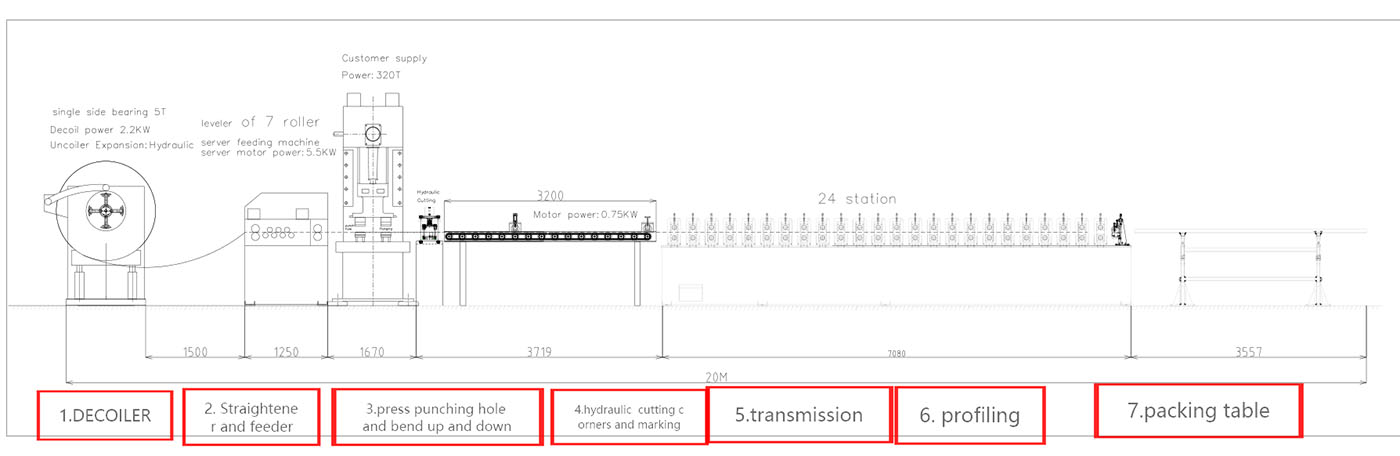

Uncoiler—Feeding—Leveling—Punching & Cutting—Roll forming—Output table

Technical Support

Fully providing technology supports both within and after the warranty period. Feed back to our customers at the first time.

Spare Parts

Promptly providing spare parts and wearing parts.

Upgrade

Italian technology German quality perforated u roll forming machine.

| No. | Item | Quantity |

| 1 | Uncoiler | 1 Set |

| 2 | leveler | 1 set |

| 3 | Servo Feeder | 1 Set |

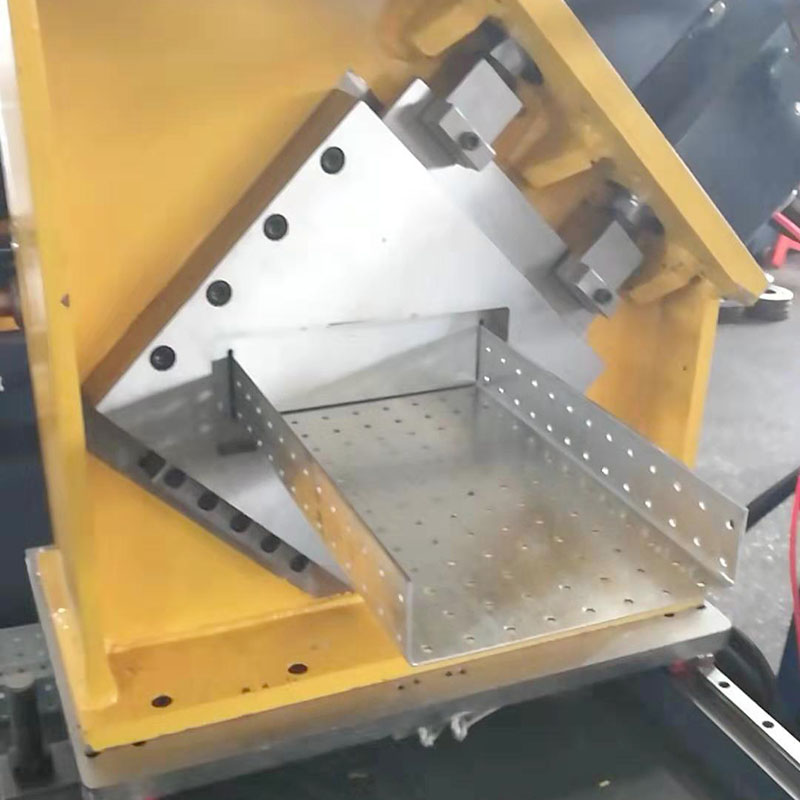

| 4 | Press machine Punching die | 1 Set |

| 5 | Lintel Roll Former | 1 Set |

| 6 | Cutting table | 1 Set |

| 7 | Hydraulic Station | 1 Set |

| 8 | Transmission and packing table | 2 Sets |

| 9 | Electrical control Cabinet | 1 Set |

A cable tray roll forming machine is a type of industrial machine that is specifically designed to produce cable trays of various sizes, shapes, and material types. It consists of a series of rollers through which a metal strip or sheet is fed, and by using a series of forming rollers, it forms the cable tray profile, i.e., ladder or perforated type. These machines are widely used in the electrical and communication industries, mainly to organize and support cables and wires in buildings and industrial plants. The cable tray roll forming machine can be customized to produce various types of cable trays according to specific requirements.

We are a factory with over 10 years' experiences on manufacturing Roll Forming Machines.

We have our own powerful research and development team.

We have more than 15 technicians.

Engineers with more than 20 years experience.

We have advanced Laser Cutting Machine, CNC Machining Center, Polishing Line, Painting Line, etc. These advanced production equipment guarantee that the good quality of each part and the appearance of our machines.

Our machines have reached the International Inspection Standards.