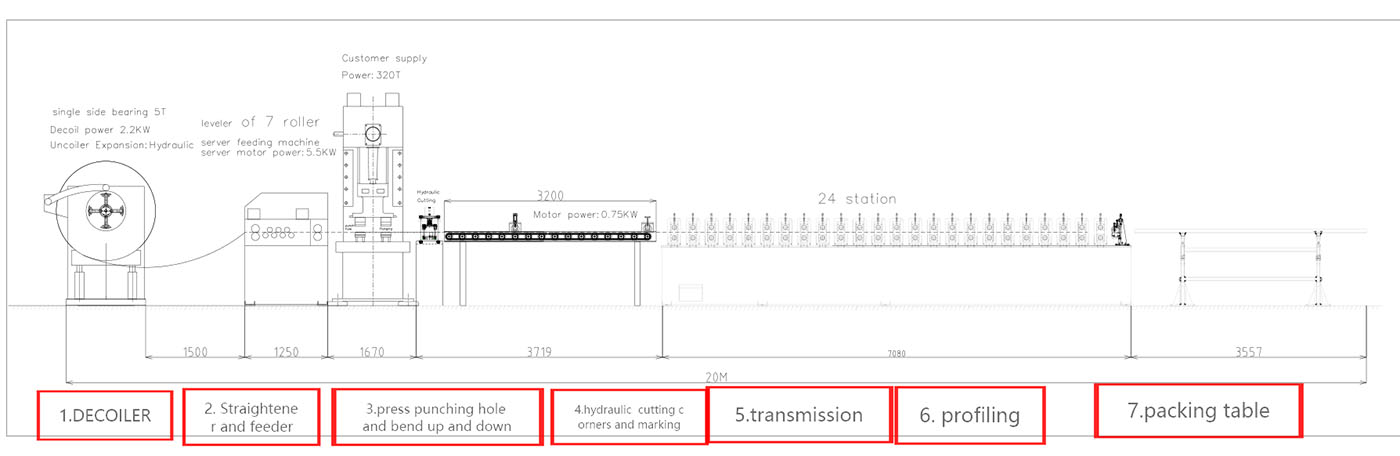

Automatic quality 10-25m/min forming speed control cable tray roll forming machine

| 5 ton hydraulic De-coiler | Diameter: 420-560mm hydraulic expansion. Pictures for reference Expansion: Hydraulic de-coiler Capacity: 5000kg per mandrel Max Coil Width: 1250mm |

| Leveling device | 1.7 rolls leveling, 3 rolls up and 4 rolls down 2.Diameter is Ø 80mm, chrome and HRC60 heat treatment to secure the smooth surface 3.Leveling Raw Material thickness:1.5-2.5mm 4.Max Leveling Raw Material width: 1000mm |

| Feeding device | Feeding Servo feeding motor: about 4.4KW,Yaskawa Description: servo feeding can control the punching distance in precision, controlled by PLC, and the feeding tolerance can be+-0.05mm, the servo motor can control the speed, and can accept the input signal, and react quickly, and performance well, the touch screen can display the rotating speed, the length and the quantity, it can be controlled by the manual and auto modes. |

| Punching press machine | 1 Series JH21-160 Brand name: Yangli |

| Main roll forming machine | Suitable Plate Material:Material thickness:1.0-2.5mm Raw material: Galvanized steel and black steel sheets Working Speed: 10-25meters / min Forming Steps: 18 stations Material of Roller: CR12MOV vacuum heat treatment 58-62HRC Bearing :NSK Japan Driven system: gear box, shafts diameter 70mm Main Power with reducer: 22KW SIEMENS Cutting: Hydraulic Cutting Material of Cutting blades: SKD11 (Japan) Hydraulic Station Power: 11KW SIEMENS |

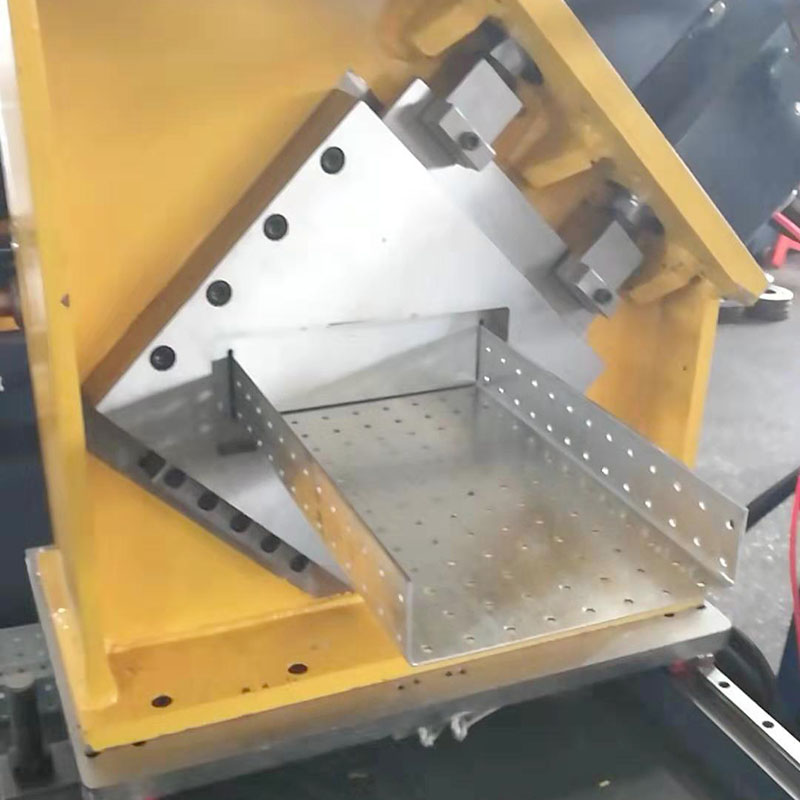

| Hydraulic cutting system | The cutter blade material: SKD11 HRC58-62 degree Cutting after forming: Cut the sheet after roll forming to required length Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start. Material of blade: SKD11 VACUUM HEATTREATMENT 60-62HRC Length measuring:locating pin fixed cutting off between two row holes Tolerance of length: 6m+/- 1mm |

| Control panel | (1) Power supplier: 380V, 50 Hz, 3Phase (adjusted with the requestment) (2) Length & quantity measurement automatically; (3) Length & quantity controlled by PLC (4) Length inaccuracy can be amended easily. (5) Control panel: Button-type switch and touch screen (6) The language in the touch screen: English and Chinese (7) Unit of length: millimeter (switched on the control panel) |

| No. | Item | Quantity |

| 1 | Uncoiler | 1 Set |

| 2 | Servo Feeder | 1 Set |

| 3 | Hydraulic Punching Device | 1 Set |

| 4 | Cable Tray Roll Former | 1 Set |

| 5 | Hydraulic Cutting | 1 Set |

| 6 | Hydraulic Station | 1 Set |

| 7 | Ran-out Table | 2 Sets |

| 8 | PLC Control System Cabinet | 1 Set |

What's the services?

We provide the technical support for whole life.

Meanwhile, if any parts go broken and not artificial damage, we will send you new ones for free.

When need the technician to go abroad, we will arrange the technician.

But the buyer should take all the cost, including Visa, Round trip ticket, suitable accommodation and pay the service fee to the technician with $100/days.

We are a factory with over 10 years' experiences on manufacturing Roll Forming Machines.

We have our own powerful research and development team.

We have more than 15 technicians.

engineers with more than 20 years experience.

We have advanced Laser Cutting Machine, CNC Machining Center, Polishing Line, Painting Line, etc. These advanced production equipment guarantee that the good quality of each part and the appearance of our machines.

Our machines have reached the International Inspection Standards.