100-600mm width cable tray roll forming machine

| Material | Galvanzied steel coil; Stainless steel coil; Aluminium sheet coil |

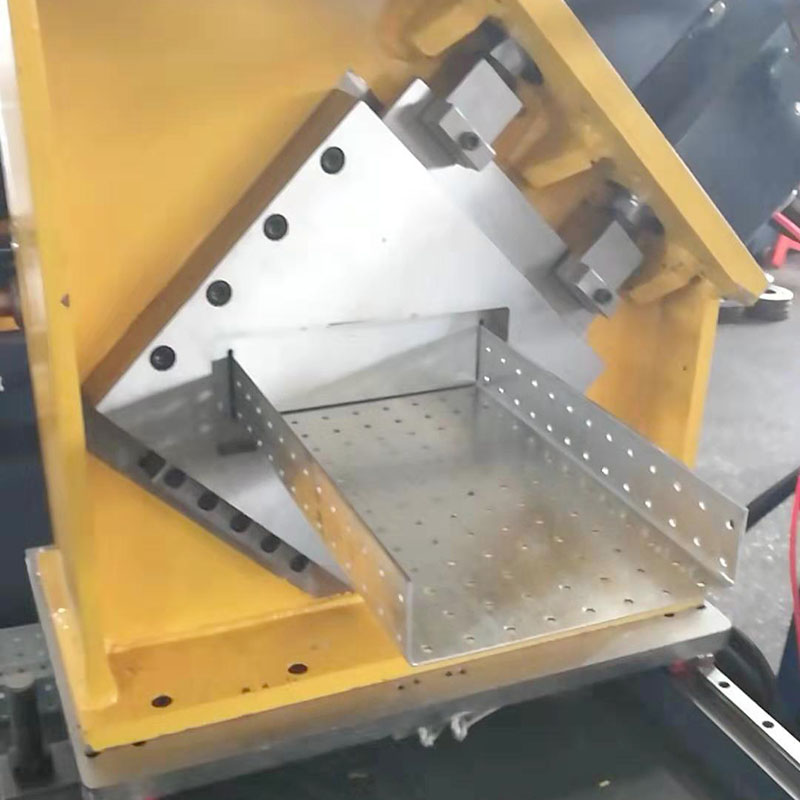

| Cable tray type | Trough type, ladder type, trays type |

| Cable tray width | 100-600mm |

| Cable tray height | 50-200mm |

| Thickness | 0.6-2.0mm (for GI sheet and coil) |

| Feeding width | 200-1050mm |

| Strength | Q235Mpa |

| Speed | 10-30m/min |

| Size tolerance | 1mm |

| Size changing way | full automatic |

| Power | 4*4kw+7.5kw+9kw |

| Roller material | #45 forged steel with hard chrome treatment |

| Cutter blade material | SKD11 VACUUM HEAT TREATMENT |

| Dimension | 20000*2500*1500mm (L*W*H) |

| Total weight | about 30tons |

Are you trading company or manufacturer?

We are factory.

How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Do you provide samples? Is it free or extra?

Yes, we could offer the sample for free charge but do not pay the cost of freight.

What is your terms of payment?

Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Packaging

1. Tighten to container with steel wire rope and welded machine with container by angel iron.

2. Main forming machine and un-coiler is naked (If you need we can also packed with water-proof plastic).

3. PLC contral system and motor pump are packed with water proof paper.

Shipping

1. 2 PC 40"container HS:8405221000

(Processes)

First step:

Designing. After order confirmation, we start to design the machine, such as the basement, structure, rollers, shafts, power, cutting device, programs and so on.

Second step:

The main parts, like rollers and shafts are produced by ourselves. We have several high-precision CNC lathe and other kinds of new machine tools, so that the quality and precision can be controlled.

Third step:

Assembling. The machines are assembled by technicians with years of experience, which can help workers improve the production efficiency and machine’s quality.

Fourth step:

Test. Raw material of different specifications are prepared for testing. And during test, long enough material is used. Because if the material is not long enough, some defects can not be exposed.

Five step:

Delivery. Because of the weight of machine itself, the packing is usually bare packing. Machine will be fixed inside container by steel wire, in order to make sure it won't move during transportation and avoid any kinds of damage of machine and container.