Roll forming production line of profiles CW; UW and CD

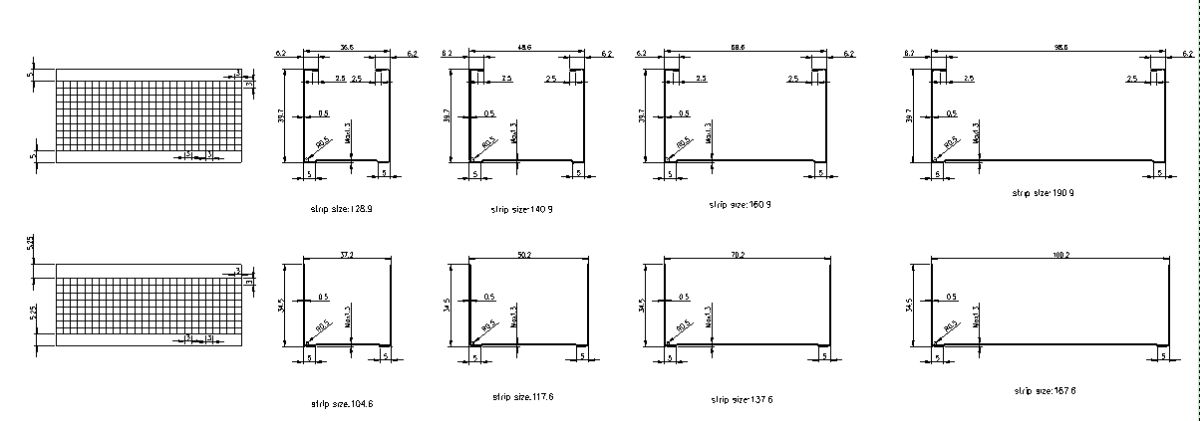

5pieces profiles drawing

Thickness: 0.40 - 1.2 mm Width: 50, 75, 100, 120, 150 mm Lenght : 3000 m

Production speed

Roll forming production speed is 60 running meters of profile per minute

Product tolerance

Profiles are available in lengths of 3000 mm; 3500 мм; 4000 мм; 4500 мм; 5000 мм; 6000 мм

|

Profile options |

Maximum deviations, mm |

|

Wall height and shelf width |

± 0,5* |

|

Profile length: ≤ 3000 мм / mm > 5000 мм / mm |

± 3,0 ± 4,0 ± 5,0 |

|

Waviness in wall or shelf plane, caused by tensions due to rolling |

Высота h волны не более 3 мм** / Height ‘h’ of the wave less than 3 mm** Длина l волны не менее 200 мм*** / Length “l” of the wave is at least 200 mm*** |

Total power: 32.05kw

Voltage:220-230v 3-phase 60hz

De-coiler motor:1.5kw

Motor in roll forming machine:15KW

Motor in hydraulic station power is 11 kw

Cutting and punching Servo motor:4.4KW

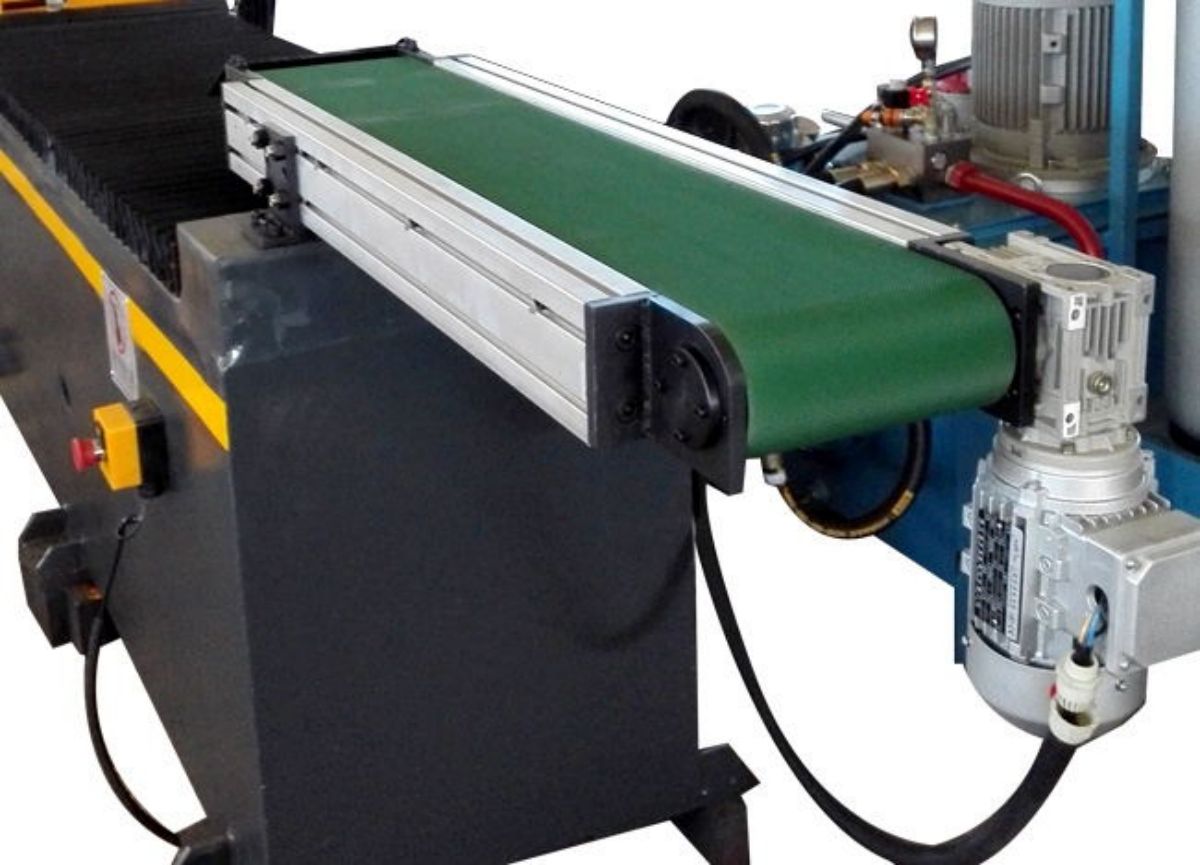

Transmission power:0.15kw

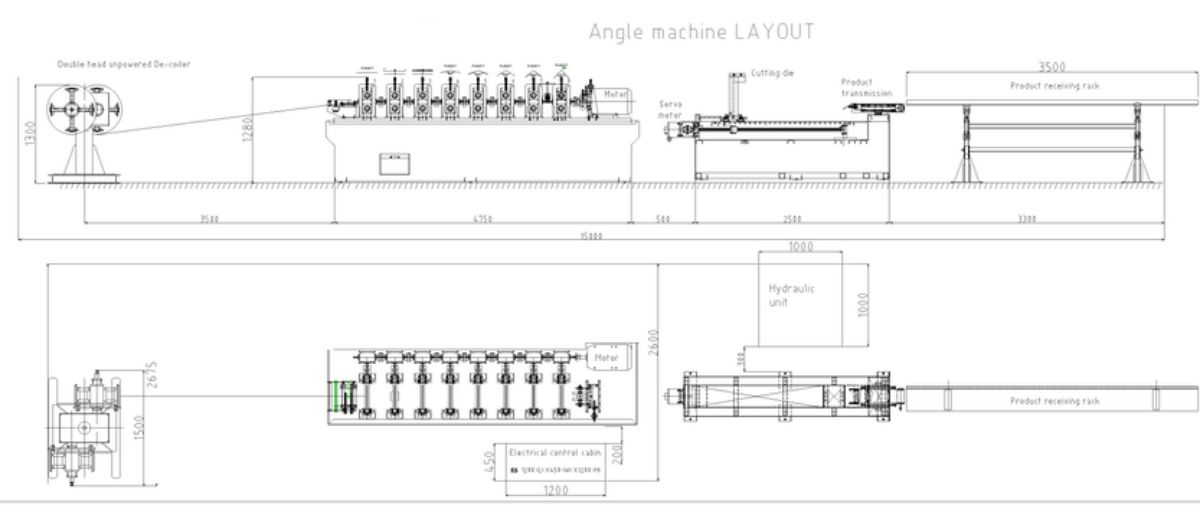

Layout of production line

Production process:De-coiler →roll forming profile →cutting table (hydraulic system given power) all parts were control by electrical control system

|

No. |

Items |

Function introduction |

Quantity |

Unit price USD |

|

1 |

Hydraulic de-coiler |

1.1 Loading max capacity:6000kg=3000 Kgs*2 1.2 Coil specification: O.D. 1,500 mm. I.D. 508 mm. Plate width:300 mm. 1.1 By hydraulic rolling in to tighten the coil.

|

1set

|

5,800.00

|

|

2.1 |

Roll forming machine base

Product |

2.1.Motor with one big reducer Power:15KW Brand SIEMENS/TECO 2.2. Reducer: import from Taiwan 14pc 2.3 The machine base material is Q345-B steel by elevated temperature to eliminate inner force for prolong machine life 2.4 The machine working table using large CNC whole processing for high precision flatness

|

1set |

15,120.00 |

|

2.2 |

Stud and track Roller unit |

2.21.Roller row:14steps+(correct straight) 2.22.Shaft diameter:Φ50mm,material-40Cr,heat treatment 2.23.Roller material:Cr12MoV vacuum heat treatment hardness:58-62HRC 2.24. wall frame:14 steps 2.25.cassette board 2.26 bearing :14 steps CU 2.27 shaft:28 pc 2.28 Wall frame material: Q345 - B, CNC processing, distance is 0.02mm between frame and slider.

|

1 |

23,250 |

|

3

|

Flying shear cutting table

|

3.1 Cut mold:4 sets .Material:SKD11 vacuum heat treatment, hardness 58 - 62HRC

3.2 Guide rail and ball screw brand: TBI(Taiwan) 3.3 Cylinder:ARITAC 3.4 Servo motor brand Yaskawa 4.4kw 3.5 Working table with large CNC whole processing, the working table is high precision 3.6 Cutting table is welded as box body structure by one type put screw and guardrail inside for safe and durable cutting table installed screw oiling device 3.7 The left and right ends of the cutting table are provided with a dust cover, a protecting screw and guide rail 3.8 Cutting table base using Q235B steel gas protection welding, after 2 times the overall tempering, eliminating the internal force generated by welding. Using sand blasting, spray 2 times 2 times anti rust primer, top coat, paint color is gray. |

1set

|

16,550.00

|

|

|

||||

|

4 |

Hydraulic system |

4.1 Hydraulic pump flow:25L/min 4.2 Motor power:11KW;SIEMENS 4.3 Hydraulic solenoid value number:3 sets, SIHUA 4.4 Hydraulic accumulator capacity 25L 4.5 Tank volume:220L 4.6 Oil pump is plunger pump (TAIWAN) 4.7 Pressure sensor: IFM(German) 4.8 Filtration brand is Parker(USA)

|

1set

|

6,500.00 |

|

5 |

Electric control system |

5.1 Encoder:OMRON(Japanese brand) 5.2 Frequency inverter:15KW(TECO) 5.3 PLC:MITSUBISHI(Japanese brand) 5.4 Human interface:KINCO 5.5 Relay: OMRON(Japanese brand) 5.6 Relay and breaker plug brand: Schneider. |

1set

|

10,500.00 |

|

6 |

Packing table

|

Transmission and Stacking table 3.5m

|

1 piece

|

1000.00

|

|

Total:78,700.00 Say total U.S. dollars seventy eight thousand seven hundred only |

||||

Sales condition

1.T/T Prepayment 30% of total amount to be paid within 10 days

2.T/T 70% of total amount when accept “ F.A.T” in SIHUA factory

3.Warranty period as

Roller and machine base is 36 months

Brand electricity spare part is 12months (not contain wear parts)

4.Wear parts as give spare part list

5.Processing time: the machines mentioned above will be delivered in 7-8 months after receiving prepayment

6.Guarantee:100% brand new when leaving SIHUA factory,

7.Installation: if you need installation service from us, we will send one technical engineer to your site to guide installation, take run and train the workers chargeshould be paid by the buyer including the visa, round trip tickets insurance hotel food

8.Train the worker in SIHUA factory is for free

9.Period of validity: this quotation is valid for 90 days since issued

10.The buyer paid coil steel for test machine

Look forward win-win cooperation with you

Contact :Caroline Jin Email:caroline@shrollformer.com

WhatsApp:0086 17751307259

Web:www.shrollformer.com

Head office: Shanghai Sihua precision machinery co., LTD

Add:NO.333 chuangda road QingPu District Shanghai China

Post code:201700

Factory : Jiangsu Sihua precision machinery co., LTD

Add:NO.138 dingmo road motou town rugao city Nantong

city Jiangsu province China

Post code: 226500