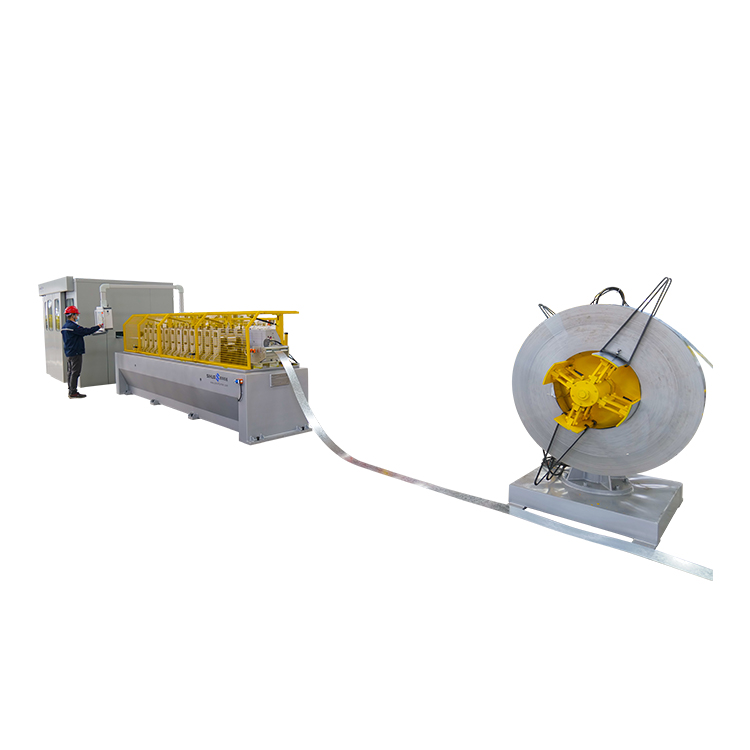

8 shear punching hole unit for solar structure channel roll forming machine

It has the characteristics of high efficiency and accuracy. The following is a detailed introduction to the product:

1. Features of 8-shear and punching unit of structural channel steel forming machine:

- Efficient production: This unit adopts advanced automated control system, which can achieve high-speed and efficient production, greatly improving production efficiency. Through the design of multi-shear punching stations, multiple processes can be completed at one time, improving production efficiency.

- Precision punching: The unit is equipped with a precision punching mold and control system, which can achieve precise punching of channel steel and ensure accurate punching position. The punching mechanism adopts hydraulic transmission, the punching intensity is adjustable, and is suitable for channel steel of different specifications.

- Good stability: Using high-quality materials and advanced processing technology, the unit has good stability and durability and can operate stably for a long time. The whole machine has a reasonable structural design, stable operation, low noise and easy maintenance.

2. Purpose of 8-shear and punching unit of structural channel steel forming machine:

- Solar bracket production: This unit is mainly used to produce the channel steel required for solar brackets. By shaping and punching the channel steel, it meets the production needs of solar brackets. Solar racking channels usually need to have a certain strength and precise dimensions, and this unit can meet these requirements.

- Structural steel processing: In addition to solar bracket production, this unit can also be used in other industries that require channel steel, such as channel steel production in construction, bridges and other fields. By changing different molds and process parameters, the processing needs for channel steel in different industries can be met.

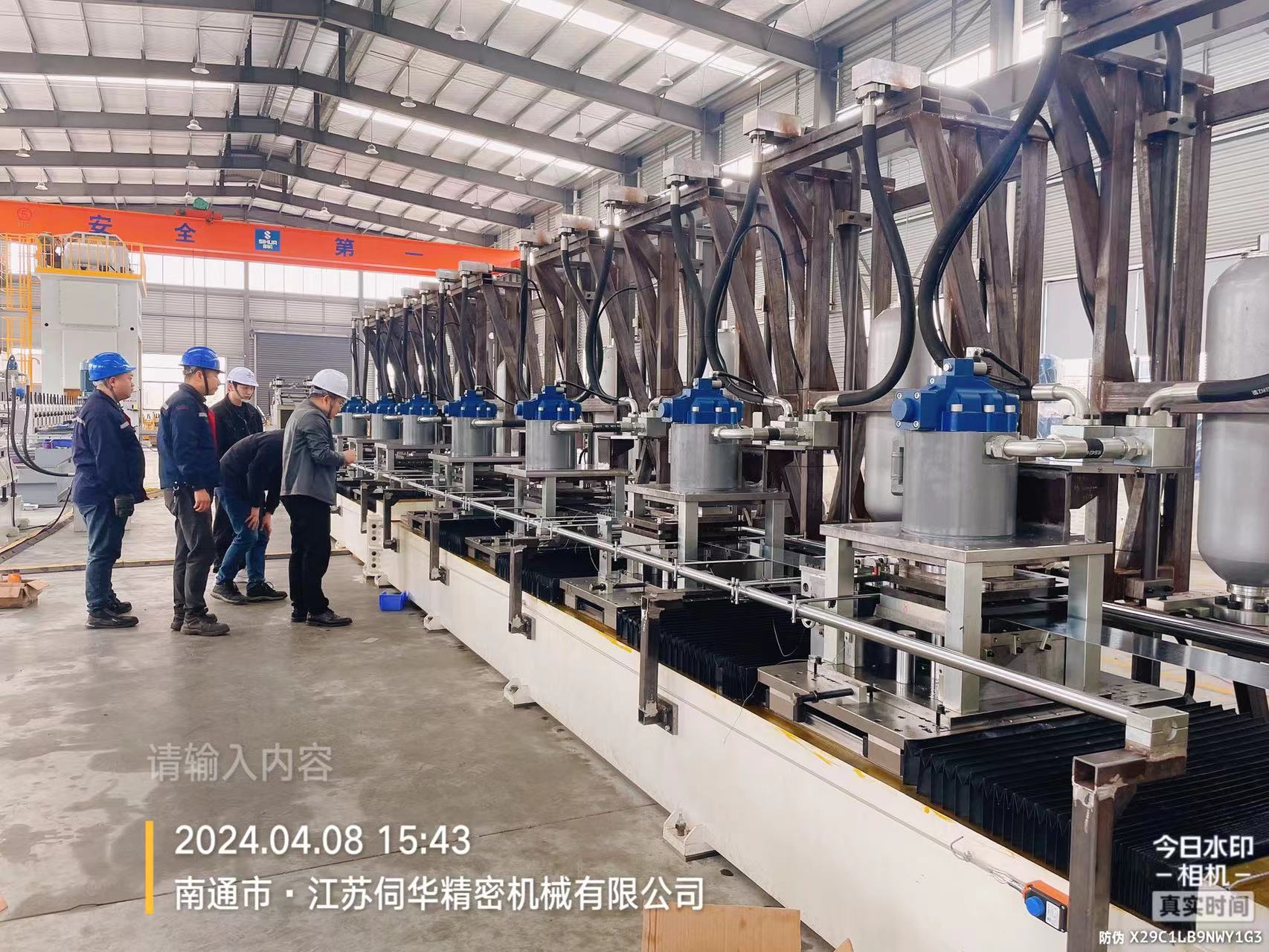

3. Product details:

- Unit structure: This unit consists of a forming machine and a punching machine. The forming machine is used for forming channel steel, and the punching machine is used for punching channel steel. The forming machine adopts multi-station continuous forming, and the punching machine adopts multi-shear punching. The entire production process is highly automated.

- Automated control: Using advanced PLC control system to realize automatic control of the entire production process, it is easy to operate and has high production efficiency. The operation interface is friendly and can realize parameter setting, production monitoring, fault diagnosis and other functions.

- Punching accuracy: The punching machine is equipped with a precision punching mold and sensor, which can achieve precise punching of channel steel with accurate punching position. The punching mold is made of wear-resistant materials, with long service life and stable punching quality.

- Safety guarantee: The unit is equipped with multiple safety protection devices to ensure the safety of operators and equipment. Safety devices such as emergency stop buttons, protective covers, and safety gratings ensure the safety of operators.

In short, the 8-shear and punching unit of the solar structural channel steel forming machine is an efficient and precise production equipment. It is suitable for solar bracket production and other industries that require channel steel. It can meet customers' high requirements for channel steel production and improve production efficiency. ,reduce manufacturing cost. At the same time, this unit has the characteristics of good stability, easy operation, safety and reliability, etc. It is an ideal equipment in the field of solar bracket channel steel production.