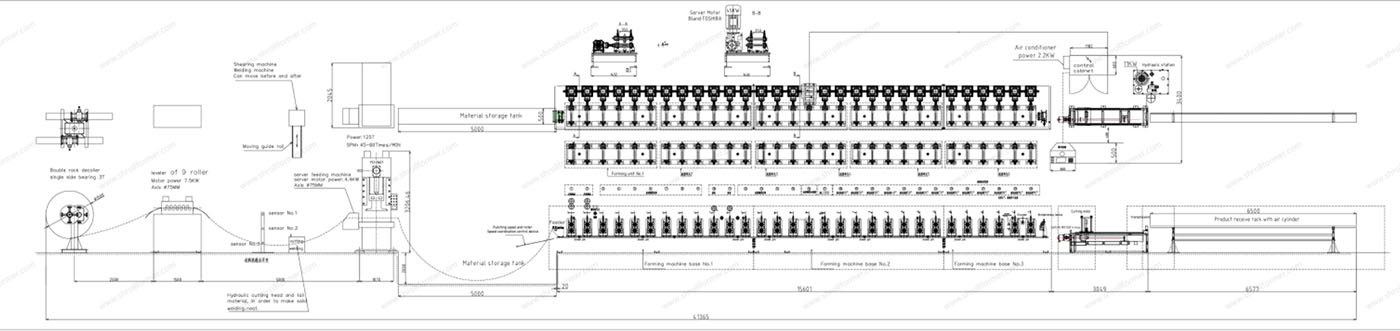

Solar pv bracket roll forming machine

This machine takes galvanized steel or cold rolled steel as the raw materials, through the a series steps to form it into a c channnel profile with specific shape and size.

The forming steps devices include decoiler, Feeding and Leveling Device, Punching device,main forming roller, hydraulic post-cutter.

The inverter controls the motor speed, the PLC system controls length and quantity automatically.

Therefore, the machine achieves a continuous automatic production,which is the ideal equipment for cold roll forming industry.

| Profile Material | A) Galvanized strip | Thickness(MM): 1.5-2.5mm |

| B) Black strip | ||

| C) Carbon strip | ||

| Yield strength | 250 - 550 Mpa | |

| Tensil stress | G250 Mpa-G550 Mpa | |

| parts of production line | Optional choice | |

| Forming station | 18-20 steps (up to customers' drawing) | |

| Main machine motor brand | TECO/ABB/Siemens | SEW |

| Driving system | Gearbox drive | * Gearbox drive |

| Forming speed | 10-15m/min | 20-35m/min |

| Rollers' material | CR12MOV(dongbei steel) | Cr12mov(dongbei steel) |

| Frequency changer brand | YASKAWA | SEW |

| PLC brand | Mitsubishi | * Siemens (Optional) |

| Shear system | SIHUA(import from Italy) | SIHUA(import from Italy) |

Introduction of struct channel roll forming machine

Production process: De-coiler →lever and feeder → press machine(contain punching die)→ roll forming profile →cutting table →packing table (hydraulic system given power) all parts were control by electrical control system.

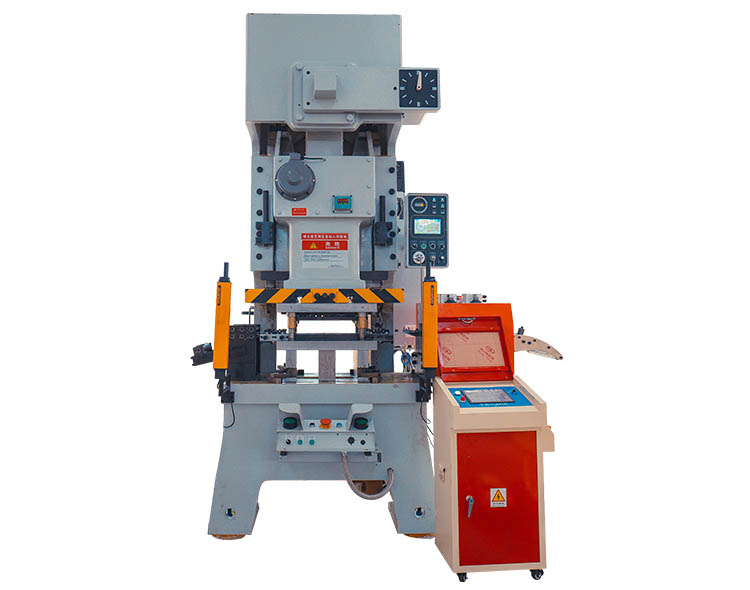

Leveler of struct channel roll forming machine.

Yangli capacity 125tons YANGLI JH21-125.

C 38*40 roll forming machine Product speed30-50m per min.

Stacking table 6.5m.

1. Encoder: OMRON(Japanese brand)

2. Frequency motor: 45KW(NIDEC)JAPAN

3. PLC:MITSUBISHI(Japanese brand)

4. Human interface: KINCO

5. Relay: OMRON(Japanese brand)