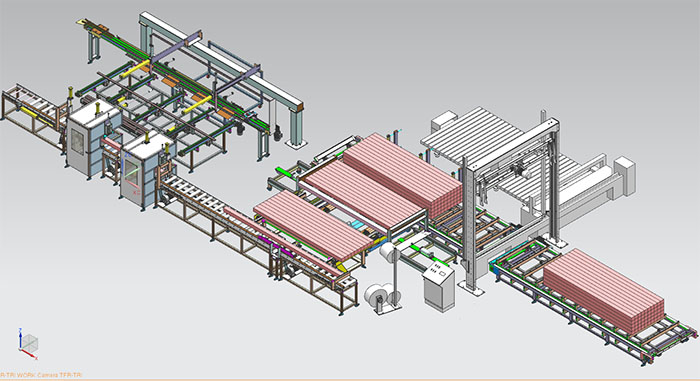

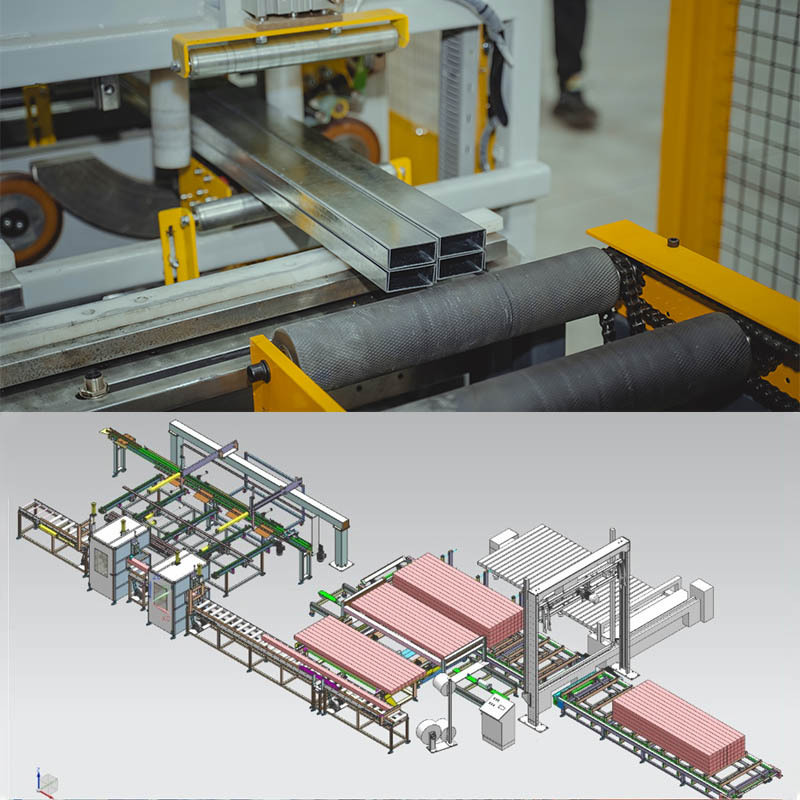

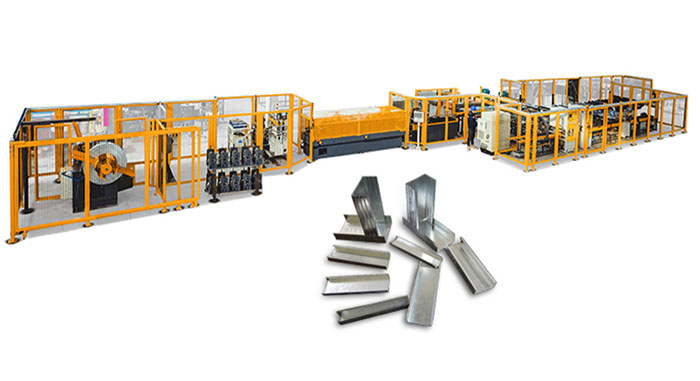

Automatic SIHUA quality and customized packing roll forming machine

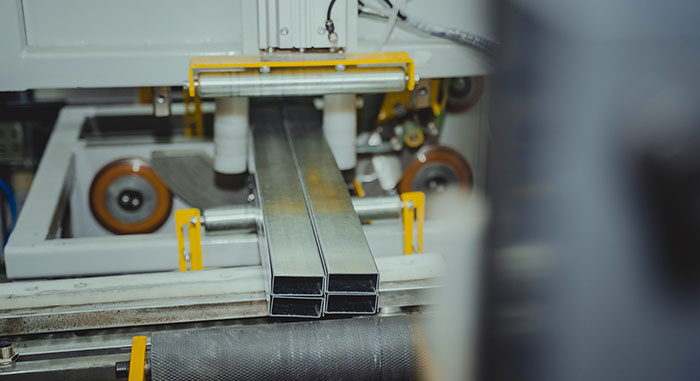

The light steel keel is a building metal skeleton that is rolled by a cooling process by high-quality continuous hot-dip aluminum zinc strip. The shape decoration of the finished non-loaded wall made of paper gypsum boards, decorative gypsum boards. Suitable for modeling decorations of a variety of building roofs, internal and external walls of the building and the base materials of the hooded ceiling.

Production process: De-coiler →roll forming profile →cutting table →packing table (hydraulic system given power) all parts were control by electrical control system.

| Rollformer | Product | Combined production speed * | Machinable gauges | Hook type | Compatibility | ||

| D54 | T4 | Cross T and Main Runner | 10 m/min | 0.2 - 0.6 mm | Integral hook | More | |

| D57 | T4 | Cross T | 31 m/min | 0.2 - 0.6 mm | Integral hook | More | |

| D58D | T4 | Cross T | 32 m/min | 0.2 - 0.6 mm | Alloy hook | More | |

| D59D | T4 | Main Runner | 34 m/min | 0.2 - 0.6 mm | Integral hook | More | |

| D51 | T4 | Cross T and Main Runner | 30 m/min | 0.2 - 0.6 mm | Integral hook | More | |

| Automation System | |||||||

| DA5MR | Main runner cardboard box packaging system | D59D | More | ||||

| DA5CT | Cross T cardboard box packaging system | D57, D58D | More | ||||

Automatic Packing system contain

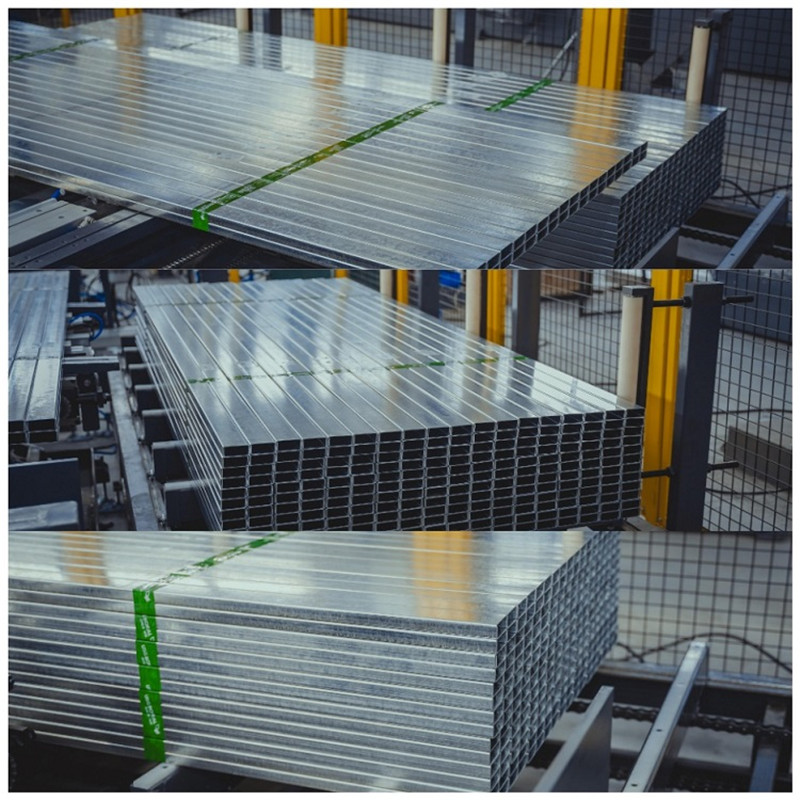

● 1st Automatic flip system

● 2nd Automatic bunding profile

● 3rd Automatic stacking system

● 4th Automatic transmission system

The first element of the packing roll forming machine automatically puts multiple profiles together into a small package. The package is then sent to the bundling area for firm fastening. From here, it goes to a third machine and stacks these packets in layers to form one large packet (the master packet). The master package can now be bundled manually or automatically sent to the last machine in the system, the automatic bundler.