Shanghai quality SIHUA main ceiling t grid roll forming making machine

T-Bar production line can be monitored by PLC. If the T-bar production line has errors, the PLC will locate the errors. It is easy to maintenance for workers.

The speed of T-Bar Production is in 0-80M/min. Average speed is 36m per min. One minute can produce 10PCS length 3660mm (12FT) main-Tree.

Different specifications Roller forming units(6) can be replaced in 30 minutes, 24X32H specifications can be produced if add one set roller forming units(6).

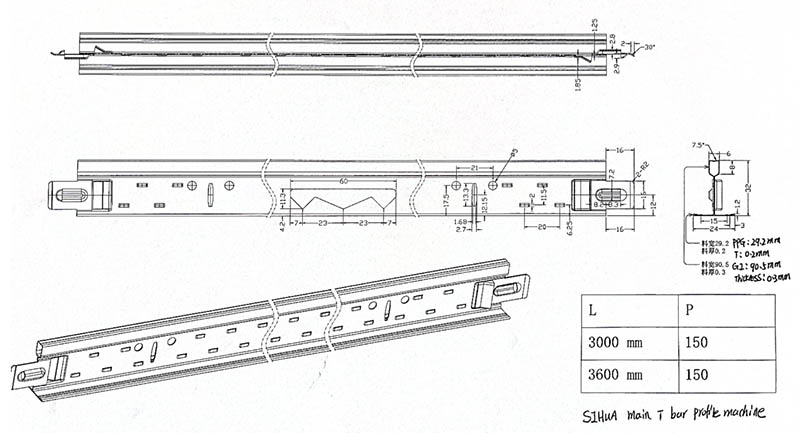

Product drawing: 38h *24*3600mm / 38h*24*3000mm.

We design the machine do according to your confirmed drawing.

Motor power is 15KW, brand is ABB.

The machine base material is Q345-B steel by whole heat treatment to eliminate inner force for long machine life.

The machine working table uses large CNC whole processing for high precision level, flat tolerance within 0.05mm, the space within 0.02mm in the roller forming units or locating pin.

Roller forming units (COMBI)are fixed on the machine base. COMBI can be replaced according to different t bar sizes.

Punching die uses the material of SKD11 with vacuum heat treatment, Hardness is HRC 58 – 62.

Install 6 pieces punching holes dies.

Cut-off length :3660mm 3600mm T-BAR mounting holes, Connector by hydraulic punching. The robot carries the Punched t bar to the stacking table.

PLC brands: MITSUBISHI (JAPAN).

Frequency inverter power: 15 KW brand: YASKAWA(Japan).

Relay and breaker brand: Schneider.

Man-machine interface (touch screen) brand: KINCO, size 10.4".

Electric cabinet, connected outside wire by the quick plug.

Servo motor power: 7.5KW, Motor brands: Yaskawa (Japan).

Pump working pressure: 140 kg Hydraulic flow: 65L Brand is HYDROMAX (Taiwan).

Oil cylinders, quantity: 9 pieces 10.4, Accumulator:25L Brand: OLAER(French).

Pressure sensor, IFM (German) The electromagnetic valve: Rexroth (German).

Filtration brand is Parker (USA).

The oil is cooled by water or by air (as customize).

Loading capacity: 3000 Kgs*2

Coil specification: O.D. 1,500 mm. I.D. 508 mm. width: 150 mm

By hand rolling in to tighten the coil.

Driven by the motor. 3.5. Driven motor: 1.5kw

Loading capacity: 1500Kgs*2

Coil specification: O.D. 2,000 mm. I.D. 508mm. Paint steel coil width: 100 mm

By handing rolling to tighten the coil

Driven by the motor

Driven motor: 1.5kw