Alloy hook cross t bar roll forming machine

Process Working Flow

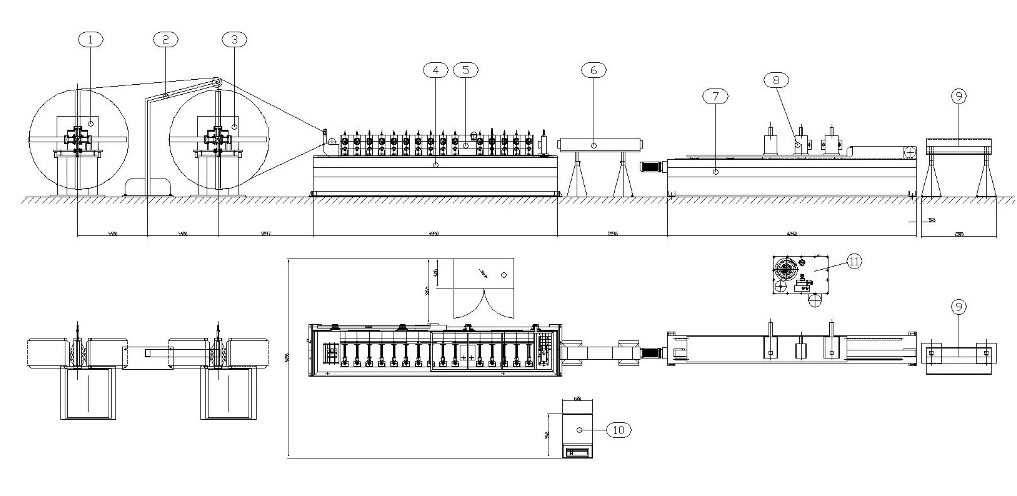

| NO. | Part Names | Quantity |

| 1 | Double motorized de-coiler (paint steel coil) | 1 |

| 2 | Storage unit for paint steel | 1 |

| 3 | Double motorized de-coiler (galvanized steel coil) | 1 |

| 4 | Storage unit for galvanized steel | 1 |

| 5 | Roll former unit of base | 1 |

| 6 | T-bar roller forming units Gear box COMBI |

1 |

| 7 | Cutting table base | 1 |

| 8 | Punching dies.8PC (6+2) | 1 |

| 9 | Control panel (Electric control system) | 1 |

| 10 | Hydraulic station Using Servo motor 7.5kw |

1 |

| 11 | Alloy hook riveting machine | 1 |

Alloy hook cross T-shaped steel bar roll forming machine is a special roll forming machine specially designed for the production of alloy hook T-shaped cross steel bars. These rails are commonly used to suspend ceilings in commercial and residential buildings. The machine works by feeding a coil of metal into a series of rollers that gradually shape and cut the metal to the desired T-bar profile. Alloy hooks are added during molding and integrated into the T-bar to provide a secure connection for ceiling mounts. The machine is highly automated and can produce T-bars at high speeds, making it efficient for large-scale manufacturing operations.

● 1 year guarantee for spare parts is included in quotation.

● Operator training in our factory is free.

● Technician could be sent for installation and operator training at site, but the fee should be discussed separately.