Shelf upright production roll forming machine

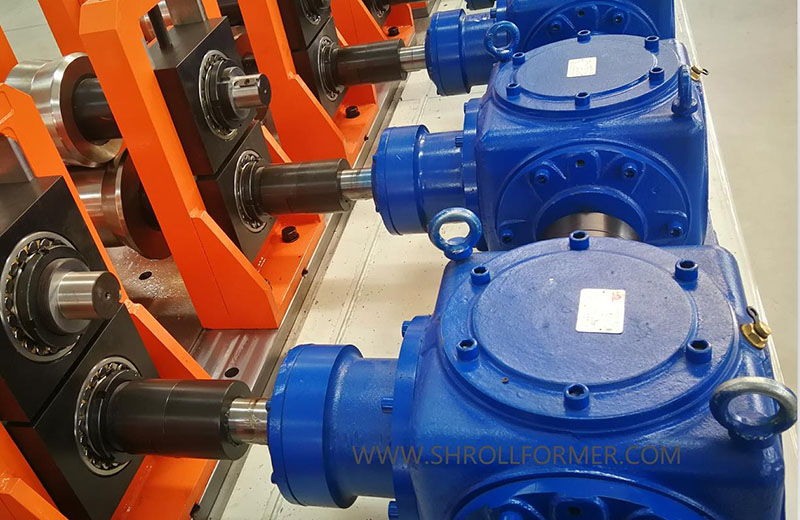

An upright rack roll forming machine is a type of industrial equipment designed to produce vertical supports used in racking and shelving systems. These brackets or uprights are usually made of metal and can be customized to meet the specific size and shape requirements of your storage system. The machine works by feeding a coil of metal through a series of rollers that gradually bend and form the metal into the desired shape. The process is highly automated and efficient, allowing high-quality columns to be produced on a large scale.

Steel racking systems are a must in storage facilities and warehouses due to their durability and efficiency in organizing products. An important component of these systems are the upright rack posts. These posts are responsible for supporting the shelves and providing stability throughout the system. This is where the vertical frame roll former comes in.

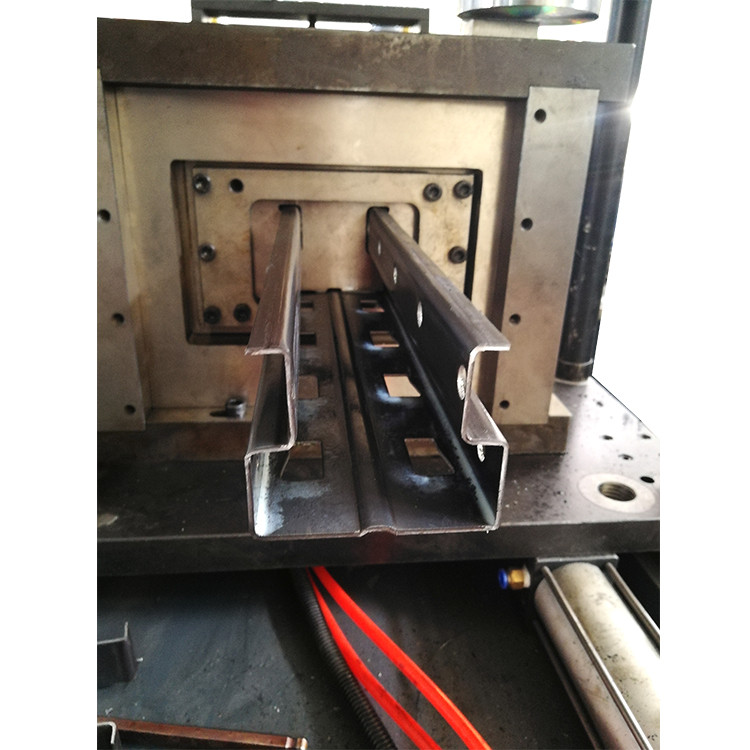

This specialized equipment is designed to manufacture these strong and durable uprights from steel or aluminum. By bending, forming and punching holes in the metal, the machine is able to produce these posts efficiently and precisely. Without it, creating an effective rack system would be more difficult and time-consuming.

If you are considering implementing a storage racking system in your warehouse, investing in a vertical racking roll forming machine is a smart choice that will greatly improve your productivity and organization.

The process of producing steel or aluminum racking systems for warehouses can be a daunting task. However, the process has become more efficient with the help of modern technology and specialized equipment such as vertical frame roll forming machines.

The machine produces basic upright rack components by feeding the metal through a series of rollers that bend and shape the metal into the desired shape. The machine's continuous punching and cutting capabilities ensure a precise and uniform finished product, making assembly easier and faster.

Additionally, this specialized equipment can be adjusted to produce columns of different sizes and shapes, making it a versatile investment for any organization. Investing in a vertical frame roll forming machine can increase your production capacity and simplify your operation, ultimately leading to greater profits and success.