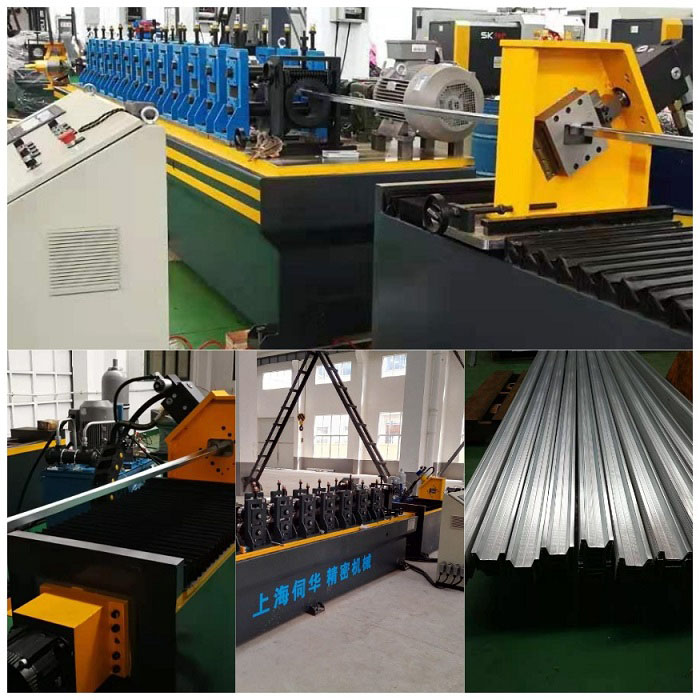

Vehicles B profile automotive chassis reinforcement beam production line

A three-in-one fully automatic uncoiler at the starting point uses servo tension control to ensure stable material feeding, while a 16-roller precision leveler eliminates material stress. Furthermore, a laser leveling system ensures sheet flatness to a tolerance of ≤0.1mm, laying the foundation for subsequent forming.

Equipped with a 600-ton large punch press and precision punching dies, it achieves ultra-high precision of ±0.1mm in the installation holes of the anti-collision beam, eliminating the need for secondary processing.

Precision punching die refers to a high-accuracy tool used in metal stamping processes to punch, blank, or pierce materials with tight tolerances and fine surface finishes.

Key Features:

1.High Accuracy – Maintains tight tolerances (often within ±0.01mm or better).

2.Fine Edge Quality – Produces clean cuts with minimal burrs.

3.Durability – Made from hardened tool steel (e.g., SKD11, DC53) or carbide for long service life.

4.Complex Shapes – Capable of punching intricate geometries with high repeatability.

5.Optimized Clearance – Proper punch-die clearance ensures smooth material separation.

A 50-pass progressive rolling process, optimized by German Copra software, ensures uniform deformation of the steel during cold bending. A real-time stress monitoring system, working in conjunction with the servo drive, maintains a dimensional tolerance of ±0.3mm on the B-shaped section. Precise arc transitions at right angles prevent stress concentration.

Roller material :CR12MOV (skd11/D2) vacuum heat treatment 60-62HRC

The production line is equipped with two TRUMPF laser welding machines in a dual-machine linkage. The main welding gun is responsible for deep penetration welding to ensure strength, while the oscillating welding head handles corner joints. Furthermore, an online visual inspection system detects weld defects in real time, ensuring that the weld strength reaches at least 85% of the base material.

Our shear controller import from italy

High precision position cutting off

Tolerance of Length of finished profile is 1mm per pices